Pseudo-Lignin Formation during Dilute acid Pretreatment for Cellulosic Ethanol-Juniper Publishers

Juniper Publishers

Abstract

Dilute acid-based pretreatment represents one of

the most important pretreatment technologies to reduce biomass

recalcitrance and it has been successfully applied to a wide range of

feedstocks. During this type of pretreatment, the relative lignin

content usually increases partially due to the loss of carbohydrates.

More importantly, it has been reported that the increase of lignin

content after dilute acid pretreatment is mainly due to the formation of

pseudo-lignin. The exact reaction mechanisms leading to the formation

of pseudo-lignin is still under investigation. However, it has been

proposed that rearrangement of hydroxymethylfurfural (HMF) or furfural

can produce aromatic type of compounds which can further undergo

polymerization reactions to from a lignin-like polyphenolic structures

termed as pseudo-lignin. This mini-review mainly covers recent advances

in understanding the fundamentals of pseudo-lignin formation during

dilute acid pretreatment, the impact of its formation on enzymatic

hydrolysis, and how to suppress its formation during dilute acid

pretreatment.

Keywords: Biomass recalcitrance; Pseudo-lignin; Dilute acid pretreatment; Enzymatic hydrolysis; Hydroxymethylfurfural; furfuralAbbreviations: MW: Molecular Weight; Mw: Weight-average molecular weight; Mn: Number-average molecular weight; BTO: 1,2,4-benzenetriol; DMSO: Dimethyl Sulfoxide; HMF: Hydroxymethylfurfural

Introduction

Pharmaceutical excipients

Increasing global energy demand and environment

concerns have led to rapid development of converting renewable resources

such as lignocelluloses biomass to biofuels such as cellulosic ethanol

[1]. Relatively high costs associated with the bioprocess and the

sub-optimal yield of ethanol production remains a great challenge due to

the natural resistance of the plant cell wall to enzymatic

deconstruction. As a result, a chemical or physical pretreatment is

usually required prior to the enzymatic hydrolysis step to disrupt the

lignin-hemicellulose matrix and increase cellulose accessibility, which

subsequently increases the following hydrolysis efficiency [2].

Over the past decades, different pretreatment

technologies have been developed to reduce biomass recalcitrance [3].

Among all the available pretreatment technologies up-to-date, dilute

acid-based pretreatment using a variety of acids including sulfuric

acid, nitric acid, or hydrochloric acid remains as one of the most

important technologies for cellulosic ethanol. It is normally performed

with acid concentration less than 4wt% over a wide range of temperature

(120 to 210 °C) [4]. It also has been applied on a wide range of

feedstock such as poplar [5], switch grass [6], wheat straw [7], rice

straw [8], bagasse [9], maize stems [10], and corn stover [11]. It is

well known that this acidic type of pretreatment, in the absence of an

organic solvent, is less effective in terms of lignin removal, and in

fact, the relative content of Klason lignin is normally found to be

increased after dilute acid pretreatment. For example, Foston et al.

reported that the Klason lignin content significantly increased from

~25% to ~40% after dilute acid pretreatment of Populus [6]. This is of

course partially due to the loss of carbohydrates especially the

hemicellulose during pretreatment. However, Sannigrahi et al. reported

that the formation of pseudo-lignin by the dehydration and

polymerization of carbohydrates should be responsible for this unusual

increase of lignin content [12]. In addition, it was also reported by Li

et al. that only ~50% of the Klason lignin extracted from a hot water

pretreated aspen was actual lignin [13].

Understanding the fundamentals of pseudo-lignin chemistry

is important from the bioconversion process perspective.

Optimization of current pretreatment technologies is often

guided b carbohydrate loss during pretreatment and lignin

residue content and/or structure after pretreatment. Lignin is

well known to effect enzymatic hydrolysis negatively due to its

physical barrier role and its unproductively binding to enzymes

[14,15]. Therefore, development of novel low pH pretreatments

with diminished pseudo-lignin formation will significantly

reduce the enzyme loadings required for an efficient enzymatic

hydrolysis, hence improve the overall process economics. In

conclusion, the formation of pseudo-lignin during any low pH

pretreatment is unfavorable as it originates from carbohydrate

degradation and more importantly, it may be even more

detrimental to enzymatic hydrolysis compared to native lignin.

This mini-review highlights recent advances in understanding

the fundamentals of pseudo-lignin formation, the impact of its

formation on enzymatic hydrolysis rate and yield, and how to

suppress its formation during pretreatment.

Structural Characterization of Pseudo-Lignin

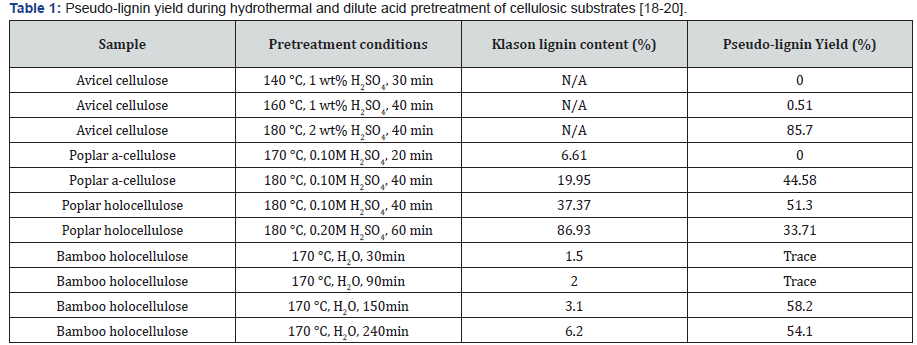

For characterization purposes, pseudo-lignin is normally

produced and isolated from dilute acid pretreated lignin-free

materials such as a-cellulose and holocellulose. Table 1 shows

some typical yields of pseudo-lignin isolated from different

resources under different pretreatment conditions. A variety of

analytical techniques including GPC, FTIR, NMR, SEM have been

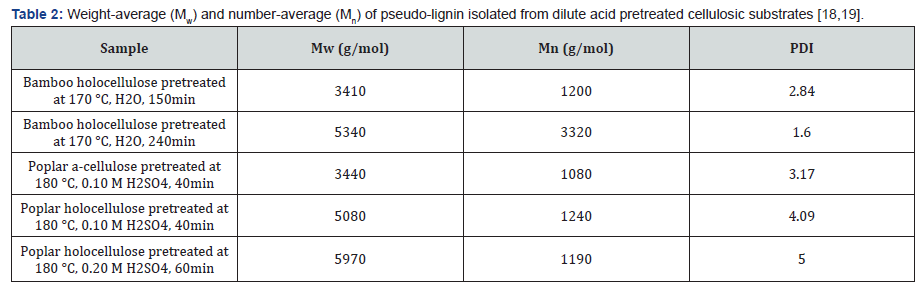

utilized to characterize pseudo-lignin. Molecular weight (MW) of

isolated pseudo-lignin from different resources is shown in Table

2. In general, the MW of pseudo-lignin is much lower than that of

milled wood lignin. For example, the weight average MW (Mw)

of milled poplar lignin and pseudo-lignin derived from dilute

acid pretreated poplar holocellulose at 180 °C were found to be

10002g/mol and 5050g/mol, respectively [16,17]. Pretreatment

severity was not found to be a huge impact factor on the MW

of pseudo-lignin (Table 2) [18-20]. In addition, MW of pseudolignin

derived from dilute acid pretreated holocellulose was

found larger than that of pseudo-lignin extracted from pretreated

a-cellulose (Table 2) [16]. FTIR and 13C NMR analysis were also

used to provide additional information on the chemical structure

of pseudo-lignin, which indicated that pseudo-lignin was mainly

composed of hydroxyl, carbonyl and aromatic structures

[12]. These results clearly indicated that pseudo-lignin was

a polyphenolic, lignin-like material with aliphatic, aromatic,

and carbonyl structures derived from cellulose/hemicellulose

fragments released during acid hydrolysis reactions.

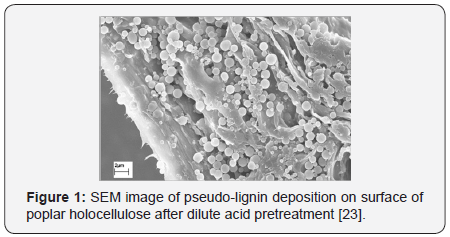

Lignin can be redistributed during dilute acid pretreatment,

leading to the formation of lignin droplets of various

morphologies [10,21-24]. During the dilute acid pretreatment,

lignin was reported to coalesce on plant cell wall and then

migrate into the bulk liquid phase in form of droplets or balls

[21]. This kind of lignin aggregation normally requires the

pretreatment temperature to exceed the lignin phase transition

temperature. Similar to this kind of re-deposit lignin droplets,

pseudo-lignin can be also exist as discrete spherical droplets on

the surface of pretreated holocellulose with a range of sizes from

0.3 to 8.0mmm [12]. Figure 1 illustrates a SEM image of pseudolignin

deposition on surface of poplar holocellulose during dilute

acid pretreatment.

Reaction Mechanisms Leading to the Formation of Pseudo-Lignin

The exact mechanisms leading to the formation of

pseudolignin

are still under investigation due to the complexity of

pseudo-lignin structure and the heterogeneity of reaction

sources and media. However, the presence of high proportions

of unsaturated carbons in pseudo-lignin structure strongly

indicated that acid hydrolysis of carbohydrates polymers to

their corresponding monosaccharide’s and the subsequent

dehydration and fragmentation of sugars probably took place

during the acid pretreatment. Hydroxymethylfurfural (HMF)

and furfural can be produced from 6 and 5-carbon sugars

such as glucose and xylems via acid catalyzed dehydration

reactions [25,26]. HMF and furfural can be further subjected to

rearrangements to produce other aromatic compounds which

might be the key intermediates for pseudo-lignin formation. For

example, 3,8-dihydroxyl-2-methylchromone was reported as

one of the main aromatic products in the acidic degradation of

xylems [27]. Similarly, hydrolytic ring-opening reaction of HMF

was reported to generate 1,2,4-benzenetriol (BTO) in yields of

46% [28]. These intermediates can be then converted to pseudolignin

via polymerization/polycondensation reactions. For

instance, it has been reported that BTO could react with HMF

or furfural to produce a three-dimensional polymer via acid

catalyzed aromatic electrophonic substitution [18]. Figure 2

summarized the reaction mechanisms mentioned above, which

highly suggested presence of acid and high temperatures are

probably two crucial conditions for the pseudo-lignin formation.

Understanding the reaction pathways leading to the formation of

pseudo-lignin will provide insights into how to suppress pseudolignin

generation, though much work still needed to be done.

Impact of Pseudo-Lignin on Enzymatic Hydrolysis

Li and co-workers reported that the lignin droplets

deposited on the surface of plant cell wall significantly inhibited

cellulose hydrolysis, mainly through surface blockage [21].

Their study indicated the nonspecific binding of lignin droplets

to enzymes was not the key source of inhibition. Similar to the

lignin redeposit droplets, pseudo-lignin formed during dilute

acid pretreatment can also exist as discrete spherical droplets

on the surface of pretreated materials, and its formation is

obviously not desired due to the fact that pseudo-lignin can

directly decrease cellulose accessibility by blocking the surface

binding sites. On the other hand, pseudo-lignin is also known

to unproductively bind to cellulase and inhibit its action [29].

Kumar et al. studied the enzymatic hydrolysis of Avicel cellulose

mixed with pseudo-lignin derived from pure xylose, and it was

reported that even a small amount of pseudo-lignin addition

could have a noticeable negative impact on enzymatic hydrolysis

yield [20]. Further protein adsorption experiments revealed

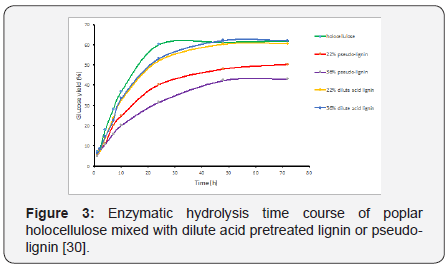

that pseudo-lignin bound to enzymes unproductively. A recent

study by Hu et al. further demonstrated the formation of pseudolignin

needed to be avoided as they proved that pseudo-lignin

is much more detrimental to enzymatic hydrolysis than regular

dilute acid pretreated lignin (Figure 3)[30]. More specifically,

dilute acid pretreated lignin only inhibited enzymatic hydrolysis

in its initial stage and had a nearly negligible impact on the

overall conversion percentage after 48 h as shown in Figure

3, whereas pseudo-lignin addition could decrease enzymatic hydrolysis yield up to 25% [30]. It is worth mentioning pseudolignin

is insoluble in water, therefore the hydrophobic structural

functionality of pseudo-lignin is probably responsible for its

nonproductive association with enzymes.

Suppression of Pseudo-Lignin Formation during Dilute Acid Pretreatment

Lignin redeposits droplets and pseudo-lignin only can

be formed at elevated temperatures, therefore reducing

the pretreatment severity is obviously one of the ways to

reduce or avoid the formation of pseudo-lignin. However,

as the pretreatment severity decreases, so do the efficient

of pretreatment in terms of hemicellulose removal and

cellulose accessibility increase. Compared to the typical batch

pretreatment, flow through reactor system was shown to

dramatically increase lignin removal as much as over 90% [31].

More importantly, its ability to constantly remove lignin into the

aqueous phase effectively restricts the condensation reactions.

As a result, flow through pretreatment can reduce the chances

of pseudo-lignin formation [31,32].Oxidative polymerization

seems to play an important role in pseudo-lignin formation

based on the proposed pathway, therefore performing dilute

acid pretreatment under non-oxygen environment could be

another possible alternative method. It was also reported that

introduction of dimethyl sulfoxide (DMSO) to the acidic medium

could effectively suppress HMF productions which is one of key

intermediates during the pseudo-lignin formation [33]. A recent

study modified a series of dilute acid pretreatment by using N2,

surfactant Tween-80, or DMSO-water mixture as the reaction

medium to test these hypotheses for new methods of suppressing

pseudo-lignin formation without significantly reducing the

pretreatment severity [34]. As shown in Table 3, addition of N2

was not effective in terms of pseudo-lignin suppression although

extra oxygen significantly facilitated pseudo-lignin formation

as expected. Apparently, introduction of DMSO significantly

reduced the pseudo-lignin content by ~30%. The coordination of

HMF with water can be reduced in the presence of DMSO due to

the stronger interaction of DMSO oxygen with water [35]. From

the reaction mechanism perspective, the reduction of HMFwater

coordination could protect the HMF molecule from further

reactions to form pseudo-lignin [34].

Conclusion

Lignin-like materials originated from acid catalyzed

dehydration of carbohydrate, termed pseudo-lignin, are

responsible for the increased Klason lignin content after acidbased

biomass pretreatment. Pseudo-lignin can be deposit on

the surface of biomass during the dilute acid pretreatment in

forms of discrete spherical droplets or balls, and it is detrimental

to the subsequent enzymatic hydrolysis, even more detrimental

than dilute acid pretreated lignin. Therefore, it became essential

to develop techniques to effectively impeded pseudo-lignin

formation. Current ongoing pseudo-lignin researches are still

quite limited to carbohydrate-derived pseudo-lignins, it is quite

possible that lignin would somehow react with carbohydrate

degradation products vis polycondensation reactions,

contributing to the yield of pseudo-lignin. The understanding

of the most fundamental chemistry associated with pseudolignin

formation is crucial for the future bioethanol production.

Therefore, future work is much needed to fully unlock the secret

of pseudo-lignin chemistry.

Acknowledgement

This manuscript has been authored by UT-Battle, LLC under

contract no. DE-AC05-00OR22725 with the U.S. Department of

Energy. The publisher, by accepting the article for publication,

acknowledges that the United States Government retains a nonexclusive,

paid-up, irrevocable, worldwide license to publish

or reproduce the published form of this manuscript, or allow

others to do so, for United States Government purposes. The

Department of Energy will provide public access to these results

of federally sponsored research in according with the DOE Public

Access Plan (http://energy.gov/downloads/doe-public-accessplan).

This study was supported and performed as part of the

BioEnergy Science Center (BESC). The BESC is a U.S. Department

of Energy BioEnergy Research Center supported by the Office

of Biological and Environmental Research in the DOE Office of

Science.

To

read more articles in JOJ Sciences

Please

Click on: https://juniperpublishers.com/jojs/index.php

Comments

Post a Comment