Optimization of Gas Lift Allocation Using Different Models-Juniper Publishers

Juniper Publishers

Abstract

Gas lift for oil-gas extraction is a common

practice; however, obtaining maximum productivity of a series of set is

not a simple tax because high amount of gas lift makes the optimization

of few wells at the same time a very hard task. Therefore, data

processing approaches based on calculations and computerized modeling

has been receiving attention. By modeling well, it could be possible to

obtain higher production rate versus less gas consumption. The present

paper is a new approach that uses neural functions and genetic algorithm

and studies the different aspects of problem solving for gas allocation

optimization in five wells. The results showed that artificial neural

networks have very good function in modeling gas lift process and

creating gas lift performance curve versus classic methods. The

differences between the results obtained by artificial neural network in

comparison with results that are obtained in classic methods prove this

claim.

Keywords: Genetic algorithm; Artificial neural network; Gas lift; Allocation optimizationIntroduction

The normal yield of an oil well does not meet the

demands of oil industry due to increasing rate of collection. For that

reason, using some methods for increasing collection is inevitable. Pump

and gas lift is one of the artificial lift approaches; however, it

could not be used in all wells with maximum power due to energy

consumption problem. In another word, gas lift in a series of well by

optimization of the approach is an economic-functional issue [1].

Studying gas lift is usually performed by using gas

lift performance curve. For the first time, Roy & Cataporan [2] used

an analytical method to create gas lift performance curve in a well.

This curve is obtained by drawing the data of oil collection values vs.

gas lift amount [3].

There are various methods for fitting the gas lift

performance curve; including line fitting by using regression and

obtaining equation coefficient. The regression method by calculating

equation coefficient is a relatively simple method for modeling gas lift

performance in oil wells; however, it lacks flexibility and does not

pay attention to the nature of data and their logic; therefore, it is

opt to be erroneous in using for different wells. In another word, the

same model could not be used in all wells. Modeling based on artificial

neural network is an approach that could be discussed due to considering

the logic of data and withdrawal from placing the data in a cliché

frame. The artificial neural network, which is mostly called as neural

network in brief, is

a mathematical model that acts by being inspired form human neural

system [4].

A neural network consist of one or few groups of

artificial connected neural cells that process data by using connective

and interactive methods. In most cases, neural networks lack

compatibility system; that is, changes in their structure take place in

learning phase and they improve themselves for modeling. Artificial

neural networks have already been used in modeling complicated relations

between inputs and outputs/entry-exits and finding existing patterns in

data. For gas lift optimization too, these functions have been used for

lift optimization particularly when it was difficult to obtain

mathematical functions [5].

The genetic algorithm (GA) is an explorative search method

that copies the natural evolution process. The algorithm model

relies on repetitions and using that repetition and accident

in genetic algorithm to optimize production and search for

maximum power. In another word, GA belongs to a larger

class known as evolutionary algorithms that is a solution for

optimization problems by using the evolutionary techniques

such as inheritance, mutation, selection and etc. [6].

GA has application in bioinformatics, calculation

disciplines, engineering, economic, mathematics, physics and

other areas. There is a history of using GA in optimizing gas

allocation of a single well or a series of few wells. Martinez

used this algorithm for the first time for optimization of gas

lift collection [7].

A combination of neural network as a model and GA as

an optimizer could be used in solving optimization issues.

In 1999, Stoisits et al used modeling of a series of well with

neural network and optimizing it with GA. Their perspective

in using this optimization system was more in the direction

of operational parameters such as the pressure of well and

lacked the intensive economical aspect [8]. In present paper,

five neural models are linked to a GA with suitable inputs for

optimizing the five wells at the same time under different

operational conditions and the economy of the process has

been summed up as well.

Development of Gas Lift Performance Curve by Modeling with Neural Network

Many models have been suggested for modeling the

amount of oil collection against gas lift. For example, second

degree model is one of those models that due to unsymmetrical

form of gas lift performance curve, it does not create suitable

fitting [9]. For this reason, other models have been suggested

by the researchers of this field. Alarcon et al. [10] in 2002

and Khishvand [11] tried to determine a suitable model. The

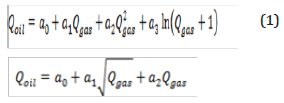

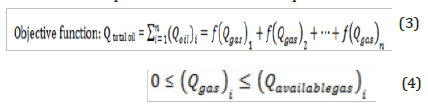

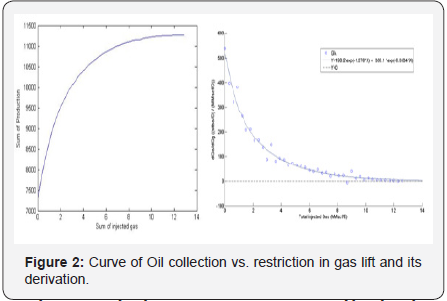

Alarcon’s model (equation 1) and Khishvand (equation 2) are

as follows:

For modeling with the neural network, a multi-layer feedforward

network with 4 hidden layers with 10 tansig neurons in

each layer was used. Then, the results of fitting the two models

mentioned above (equations 1 and 2) were used to compare

the function of the neural network model vs. mentioned classic

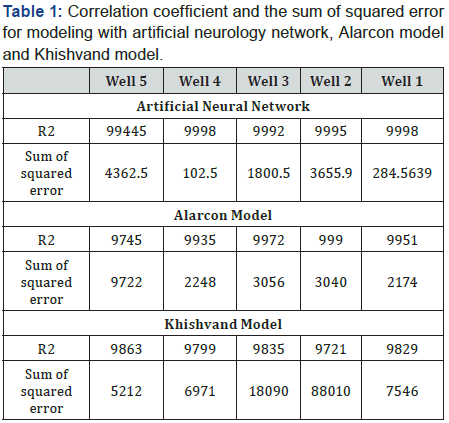

methods. The results are listed in (Table 1).

The results of Table 1 show that the artificial neural network,

Alarcon and Khishvand model has desire fitness. In addition,

as Table 1 shows, the highest correlation coefficient and

lowest sum of squared errors were obtained by artificial

neural networks. Khishvand’s model showed weaker results

in comparison with Alarcon model on the wells subject of this

paper.

It should be mentioned that the above-mentioned result

were obtained by using the most usual neural networks

without manipulating geometric parameters of the network.

Therefore, most probably, by designing network and using

more data, those results could be improved considerably. In

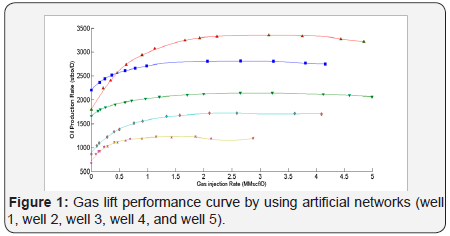

continuation, the results of drawing gas lift performance curve

by using artificial neural networks for five wells are shown

(Figure 1).

In Figure 1, the marked dots show the empirical values and

the corresponding line of each set of knot shows the neural

network model of each well. As it is shown and could be seen

in (Table 1) too, suitable agreement of the empirical values

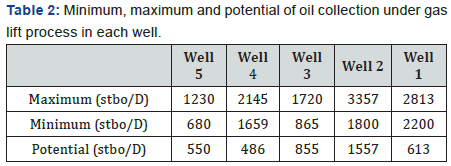

and artificial neural network could be seen. On the other hand,

by using the model of each one of the wells, quantities such as minimum collection of each well, maximum collection of each

well and potential for additional collection of each well could

be obtained. This information was obtained for all five wells

and is listed in (Table 2).

The amount of potential of increasing collection in the

process of gas lift has been obtained by differentiating the

maximum collection with gas lift and collection in no gas lift

conditions. This parameter is independent from gain without

gas lift; that is, primary conditions of wells. Due to studying

optimized answers, it is interesting to calculate this parameter

in order to find out how much the gas allocation between

wells in an optimized state would be in relationship with the

potential of the wells involved in optimization.

Unrestricted Optimization of Gas Allocation In Wells and Its Effects on Total Collection

There are different approaches in optimization of a series

of well [11]. The approaches could endure different restrictions

on the optimization issue. I any way, restrictions such as the

range of gas imposing to each well are necessary and inevitable

while restrictions such as entry gas originates from economic

necessities and studying them is a farther priority than the

conditions of gas lift for each well. In this study, we used a

trained neural function and linking it to genetic algorithm

tool box to optimize the amount of oil production of a series of

well and studying the factors. We benefitted from the method

of developing the total utilization function and the target

function in our issue in most simple situation was maximum

total production. This target function could be solved per case

without boundaries. For example, the genetic algorithm could

be used to obtain maximum total production when less gas

lift complex is accessible. In continuation, development and

solving little suitable target function is discussed by using

common concept in the literature of this discipline and some

new suggestions are proposed as well.

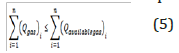

Development of the Target Function Of Total Production without Economic Boundaries and Restriction

In this situation, optimization of the sum of wells production

will be performed, conditioned by using the amount of gas

lift in the scope of model information. The proposed target

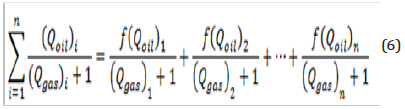

function and its requisite are described in equations 3 and 4.

Development of the target function of total production by economic restriction and studying the effects of economic restriction in productivity

This situation is like previous one with the difference

that the sum of entering gas should be less than or equal to a

constant amount. In practice, the sum of lift gas should be less

than the amount of gas in access. In addition, high costs of the

gas make this value to be as low as possible.

The amount of accessible gas might differ as per operational

conditions and therefore, it is interesting to study the effects of

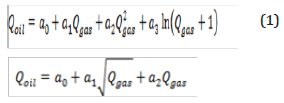

gas restriction on the maximum collection conditions. To study

this, GA was used. Figure 2 shows the results (55 points) of the

calculations. As diagram in (Figure 2) shows, change in total

production vs. restriction in total gas lift had an initially strong

function and by the increase in amount of gas, the amount of

changes and functionality vs. amount of lift restriction reduces

accordingly.

This means that by increasing as to optimized level without

restriction (last point in curve), the amount of production

increase against consumed gas will be so trivial that would not

have economic justification. Hatton et al; too, in studying a field

with one hundred wells obtained similar results [12]. In many

papers, the limit of 3 million cubic foot standard (MMscf/D)

has been defined for total gas arrival in access and observing

those conditions in our study could led to 27% increase in

oil production. Due to the importance of using least gas and

obtaining highest output, it is important to determine the

suitable degree of lift restriction. In following parts, two target

functions have been proposed for economic optimization and

their results are compared.

Suggestion of Production Target Functions for Achieving Economic Optimizations

The amount of oil production increase per gas consumption

unit could be considered as an important index in lifting operations and the largeness of number leads to economic

productivity of the oil field. For this reason, this index could

be considered as target function to be maximized by using

genetic algorithm. For this purpose, two target functions are

suggested: The function of sum of net productions of wells and

the function of net production of wells and their only difference

is in the method of modeling for gas lift production. The

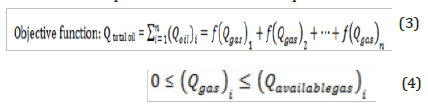

function of sum of net production of wells is defined as follows:

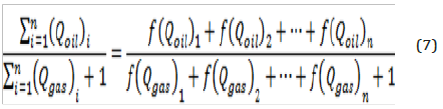

In addition, total net production function is standardized

as follows:

Economic- performance desirability of the conditions

obtained from each target function could be defined with

respect to the increase in production divided into sum of

lift gas in optimized state. The scale is million cubic foot

standard in one power (1/stbd/D). In this case, the boundless

optimization desirability of wells will be 2.75 (percent

collection improvement/ amount of lift gas), the desirability

obtained from optimization function of sum of net production

of wells (equation 6) is 17.15 and desirability of optimization

of total net production (equation 7) will be 21.59. On the other

hand, in many papers, the restricted optimization or maximum

accessible gas was concerned while in our study, by including

lift restriction of total 3 million cubic foot standard gas per day,

the perspective will end to desirability value of 9 which is less

than the desirability of suggested target functions.

Therefore, it could be claimed that it is not economical to

use all the gas accessible for gas lift project and optimizing the

amount of gas lift is a delicate issue; therefore, modeling with

neural network and optimizing with GA could be a solution.

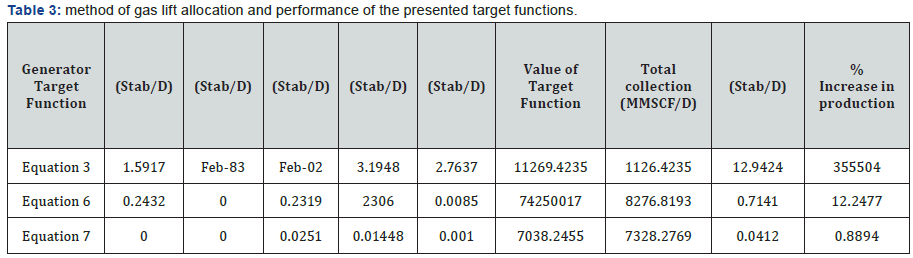

Another interesting point is the approach of gas allocation

by genetic algorithm. The arrangement of potentials magnitude

of wells subject of study is as follows: well 2, well 3, well 1, well

5 and well 4. In optimizing with target function in equations 6

and 7, as Table 3 shows, wells 4, 5 and 1 were not gas lifted and

since those functions (equations 6 and 7) show the desirable economic point too, it seems that GA has withdrawn from

optimizing the mentioned wells for maximizing economic

profit.

It is highly interesting that the mentioned wells were

among the poorest wells in the issue and potential in terms

of parameter and this shows the importance of potential

parameters in gas lift optimization process; because, if only

highly potential wells are selected as gas under lift process,

most probably, this would lead the load of optimization

calculation load and increase in lift output.

Effects of the Number Of Wells Involved In Gas Allocation Optimization

Resource management in a gas lift project could be

performed in various forms. The number of wells in optimization

process is one of the issues that are important in this regards.

As an example, in a gas lift network with five wells, the subject

could be handled in one of the following approaches:

- Optimization of all five wells by using restriction of sum of input gas

- Optimization of a number of wells without restriction and not optimizing other wells

- Optimization of a number of wells with the restriction in total entry gas and not optimizing other well

The first scenario has been receiving more anticipation;

however, scenarios 2 and 3 did not seem much favorable and

of course, no suitable comparative study has been performed

regarding those approaches. The logic of the first scenarios

is its attention to all wells proportion to their potential and

economic abilities. In addition, scenario 2 and 3 are elite

adoption scenarios and supporting highly potential wells in

production with gas stimulation and withdrawal from spending

for wells with no potentials. Each one of those scenarios could be studied with respect to the potential of production

under gas lift conditions. Here, we plan to study the effect of

the number of wells subject of study in an optimization issue

without restriction of entry gas. For this purpose, a full fivefactorial

trial design matrix was used. The optimization issues

with 0 to 5 wells involved in optimization issue were solved

by GA in accordance with the developed matrix. In addition

the total amount of gas consumption was calculated and the

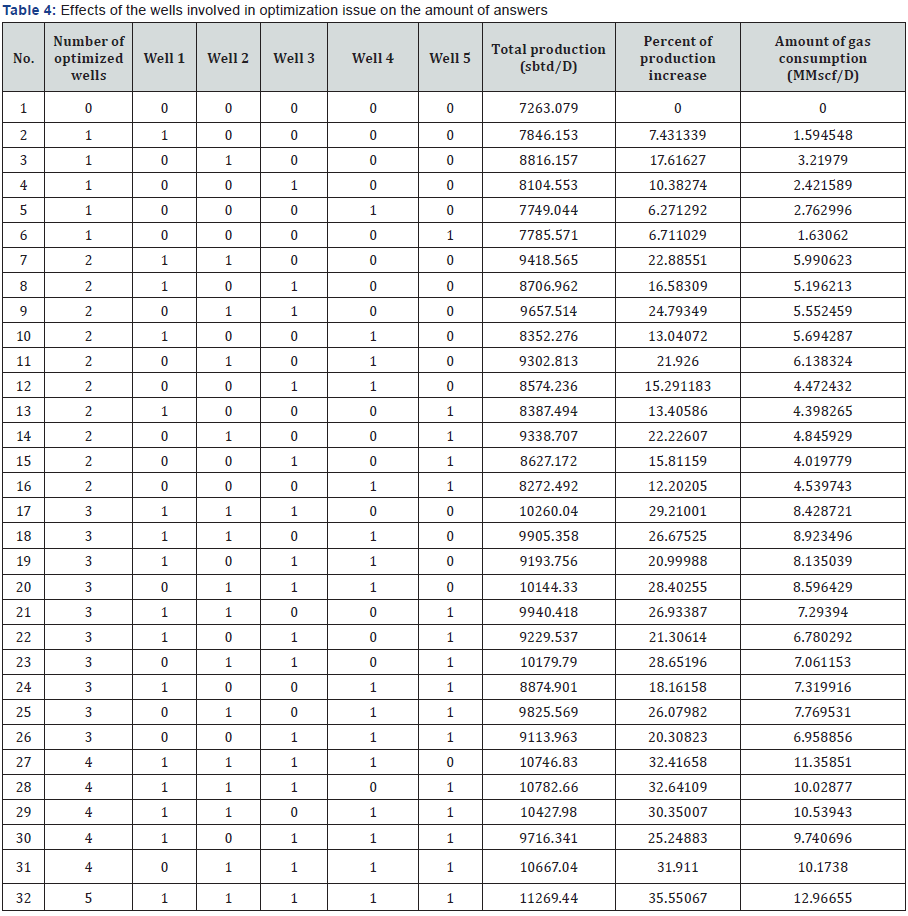

results were listed in following table

The results of (Table 4) show that by increase in number

of involved wells, the slope of production increase percentage

curve gradually moves down. In another word, for the present

five wells, it is predicted that infinite increase in the number

of wells subject of optimization will not cause an increase in

optimization output. In another word, in our study, increase in

the output caused by optimization has a limit and after reaching

that limit, the production increase percent will remain fixed.

Therefore, observations and calculations made by authors

emphasis that the irregular enlargement of the optimization

issue of gas lift does not contain economic profit especially

for the reason that the facilities and equipment of gas lift are

expensive and require using personnel of the utilization party.

In addition, enlarging optimization issue prolongs it and makes

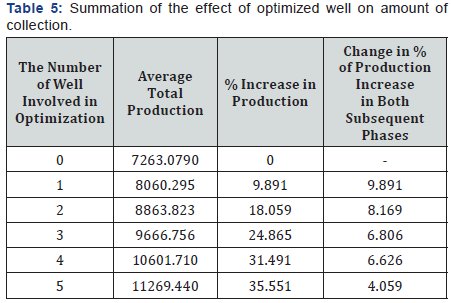

it difficult to solve. Results of (Table 5) could be used to draw

Pareto diagram and determine the general effect of each well

on total amount of collection form series of wells. (Figure 3)

shows this diagram.

As it could be seen, the effects calculated for wells

correspondence with their potentials and since measuring

potentials of wells is easier, by considering the results of Table

4, it is suggested to take the optimization spaces as small as possible and in selecting the wells for optimization, consider

the potential factor.

Conclusion

The most important results obtained in recent research

are:

- Artificial neural networks have very good performance for modeling the process of gas lift and making performance curve of gas lift in comparison with classic methods.

- Linking the artificial neural networks (as proximate function) and genetic algorithm could be easily used in optimizing gas lift to oil wells.

- Optimization of the amount of oil production simultaneously, vs., gas consumption in a gas lift without restriction and with restriction is possible. Using new target functions, particularly sum of net products of wells and net total product has more economic value compared to classic views.

- Increase in number of wells involved in optimization issue does not necessarily cause linear increase in economic productivity of total wells. It seems there is a limit and desirable number for wells involved in optimization issue and this issue, along with the cost of equipment and man force generates needs to select the bet wells for as lift.

- The potential parameter could be used as a proposed parameter in selecting wells to be optimized in order to fill the index vacuum of selecting the well.

Acknowledgement

We take this opportunity to extend our best appreciation

to South Oil fields utilization Company for providing us with

the information of wells performance curves.

To

read more articles in Recent Advances in

Petrochemical Science

Please

Click on: https://juniperpublishers.com/rapsci/index.php

Comments

Post a Comment